Discussion

Site visits versus IRIS

The site visits revealed that 42% of the schemes visited contained defects that were external to the original maintenance works or were isolated defects. The former is related to a limitation in the way that defects are referenced and recorded in IRIS. The latter relates to an exceptional defect that is not representative of the overall condition of the maintenance scheme. These defects were confined to the surface course and are likely to be associated with workmanship or quality control during laying operations. In general, the condition of the TS2010 surface courses was regarded to be good and this finding is in agreement with the results from annual surface course inspections (McHale & Martin, 2019).

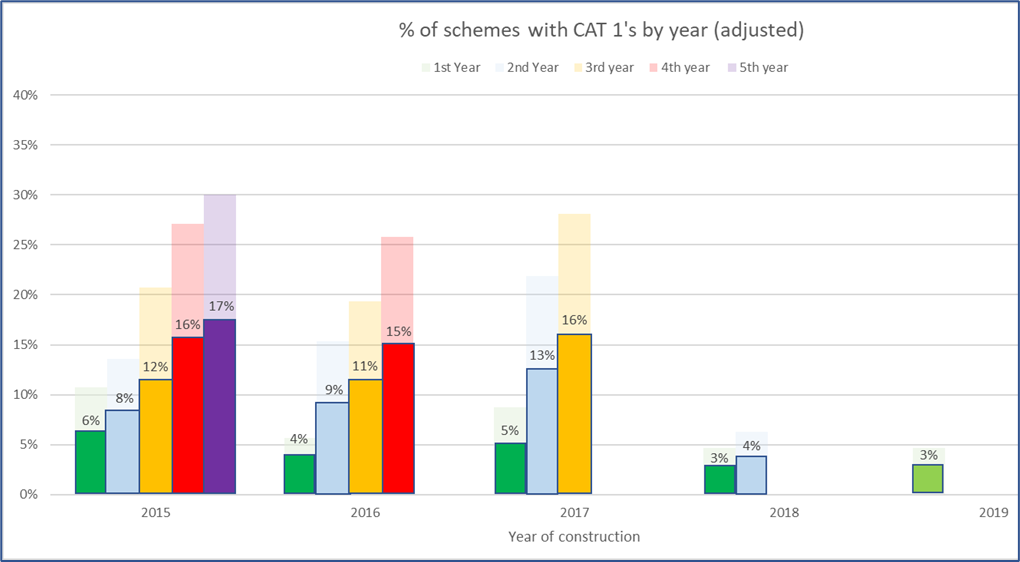

Further analysis was undertaken to examine those locations where schemes were constructed in 2015 and Cat 1 defects had been recorded in order to determine whether further treatment was required over subsequent years. The collected data showed that 30% of the sites where CAT 1 defects had been repaired required no further maintenance treatment. This provides additional evidence that supports the site visit observations, i.e. that the recorded defects were exceptional and did not represent the overall condition of the maintenance scheme.

Figure 4-1 shows that if the above findings were applied as a general correction factor, then it would significantly reduce the apparent incidence of early life defects. For schemes originally completed in 2015, the incidence of Cat 1 defects occurring within the extents of a maintenance scheme would fall from 30% to 17% after five years in service. A similar exercise would show that the incidence of Cat 2 defects falls from 40% to 24%. Similarly, the annual frequency of Cat 1 defects recorded in the first year of construction falls from 6% to 3% and from 11% to 5% for Cat 2.

Deterioration mechanisms

Substrate condition

The most common early life defects were associated with inadequate inlay depth. This was evidenced by the fact that on several schemes that contained both shallow and deeper inlays, the defects were confined to the shallow inlays. From failure investigations carried out on some of the schemes that exhibited extensive defects, it had been speculated that some of the exposed substrates, following milling, had undergone some form of deterioration, on exposure to rainfall. The inference here, is that the substrate was deemed to be in an adequate condition to receive the inlay treatment, but owing to unforeseen conditions the inlay subsequently failed following opening to traffic.

It is possible that rainfall could contribute to the breakdown of an old milled material substrate, but it is contended that the primary cause of failure on these schemes is related to the existence of a poor or unstable substrate. The surface of the substrate that directly supports an inlay needs to be in good condition and have adequate thickness to ensure satisfactory bond with the new inlay material and the pavement layer directly below. If the material condition of the substrate layer is poor, prior to or post milling, it will be unable to support the new inlay material and breakdown under traffic loads. Similarly, if the substrate layer comprises a thin lens or slivers of material it will not provide adequate bond or support to the new material. In either scenario the inlay material will not be adequately supported by the underlying substrate layer and insufficient bond will result in shear leading to excessive flexure of the inlay which will cause the material to crack. The latter will permit the access of water and subsequent deterioration is likely to take the form of potholing.

Inadequate width and drainage

Following a review of scheme documentation, several references are made to ‘evolved roads with limited drainage’. This description is typically used to describe a trunk road that has not been designed (or constructed) in full compliance with normal UK standards, such as the DMRB. Typically, these roads comprise non‑standard geometry and layout, e.g. horizontal and vertical alignment, width, drainage, etc. In certain instances, the existing road layout and geometry does not permit some HGV traffic to pass without incurring vehicle overrun at the edge of the road pavement. In general, many of these roads are not kerbed meaning that there is little lateral restraint, and the consequence is that the pavement breaks or cracks at the edge. Drainage on these roads can also only be described as rudimentary. It is highly likely that where standing water is allowed to accumulate at the edge of the pavement this will exacerbate the situation and result in localised areas of structural failure.

Urban environment

Owing to the presence of utility apparatus, urban environments present challenging conditions to carry out structural maintenance. Street furniture, utility trenches and reinstatements increase the roughness of road pavements. They also introduce discontinuities in the pavement structure, which can affect the pavement's expected life span. For the two sites visited as part of this project, two main types of deterioration were noted: functional and structural. The former relates to loss in profile owing to rocking street furniture and subsequent surface defects. However, it should be noted that loss of profile can result in dynamic effects increasing loads on the pavement that can lead to structural failure. The latter relates to sections of the pavement where large deflections or deformations have occurred owing to the existing pavement structure not being adequately supported at depth.

On one of the schemes, small targeted sections received inlays to a depth of 250 mm. The fact that some of these area have continued to fail following treatment suggests that the material directly below is soft or weak and needs to be replaced.

Potential solutions

Optimising inlay depth

The surface course of a road pavement is commonly replaced or treated owing to some form of deterioration, such as polishing, fretting, cracking and poor profile. Dependant on the condition of the pavement and height restrictions, the existing surface is commonly removed by milling, or cold planing, and replaced with new asphalt in a process which is called an inlay. In terms of efficiency, there is a good case to minimise the thickness of an inlay as it reduces both material and energy costs. The availability of modern surfacing that makes use of smaller aggregate sizes and high binder contents, also means materials can be successfully laid and compacted in thinner layers.

This study has highlighted that the benefits of shallow inlays, i.e. less than 100 mm, need to be balanced against the risk of an early life failure. There is a real risk that a shallow inlay may not be the most appropriate choice if the stability of the substrate is compromised. The substrate needs to be in a sound condition and provide adequate bond with both the inlay material and the pavement layer directly below. A review of the available design data used in this study suggests that core data is not sufficient in itself to determine whether the milled substrate will be sound. However, material thicknesses from the extracted cores can be used to predict where the proposed inlay will sit within the treated pavement.

Where an existing surface is being replaced to a depth of 50 mm thickness or less, special care needs to be taken to ensure that the condition of the substrate is sound. The following factors should be taken into account when proposing a shallow inlay.

Assessment of deteriorated surface course

Fretting and ravelling of modern surface courses are recognised to be the most common distress mechanisms. The process involves the progressive loss of fine mortar and aggregate from the surface of the mixture owing to the action of trafficking and weathering. These materials commonly present an open and porous appearance. When this type of material is being replaced, consideration should be given to the possibility that owing to its higher permeability, water infiltration and water retention may have caused a partial breakdown of the layer below.

Similarly, attention should be given to other surfaces that are badly cracked and the possibility that the lower layer has undergone some deterioration.

Substrate thickness

It is important that the in situ substrate thickness is not too thin. The substrate thickness can be estimated by subtracting the proposed inlay depth from the top of the original surface and measuring the distance to the next layer interface. If the thickness is less than 25 mm, consideration should be given to increasing the inlay depth.

Inspection of milled substrate

It is essential that all defective material is removed to provide a sound, uncracked surface to which the new asphalt can firmly bond. This is to prevent any defective residual material affect the performance of the treated pavement.

The condition of the of milled surfacing should be inspected thoroughly following brushing and prior to surfacing operations. It is essential that lenses or slivers of asphalt are not present on the planed surface as these could present potential slip planes at the interface with the new asphalt. If it is not possible to examine the surface properly, e.g. night-time working, then consideration should be given to increasing the inlay depth.

It should be noted that a greater inlay thickness, i.e. ≥ 100 mm, will reduce the stresses at the interface of the substrate. Dependant on the degree of deterioration and the depth relative to the new surface, the risk of failure of a sub-standard substrate is significantly lower when located lower in the pavement. For this reason, if any of the factors described above cannot be evaluated then increasing the inlay depth will result in a lower risk of early life defects.

Non-standard designs

Two of the schemes visited displayed significant defects at the pavement edges after 2.5 years. One of the sites on the A82 near Aonach Mòr received extensive treatment. The entire site was milled to a depth of approximately 150mm and then replaced, with 50mm of AC20, a pavement reinforcement system (Tensar), 60mm of AC20 and final 40mm of SMA. The design was developed to address the presence of a reinforced concrete slab which had been discovered at depth and which had caused transverse cracking and the breakdown of the original overlying asphalt.

At the time of the visit several defects were noted which were confined to the outer edge of the pavement and could have been related to the edge of the lower concrete slab. However, some of the defects were observed to be of a structural nature (see Figure 4-2). This road is a rural single carriageway with an average width of 6.1m and limited drainage. It is recognised that these types of road are not uncommon on the Scottish network and it is possible that some pavements perform better than others owing to the presence of natural free draining and favourable ground conditions. Nonetheless, it is recommended that where excessive vehicle overrun and damage is identified at the design stage, then road widening and improved drainage must be considered. Notwithstanding the adoption of this advice, it should be expected that the life span of these type of roads will be shorter than would otherwise be the case and hence the appearance of early life defects will continue to occur.

Urban environment

Carrying out structural maintenance on a road pavement that has failed owing to a high density of utility apparatus, reinstatements and street furniture is challenging. There is a high likelihood that many of the surface defects encountered in an urban environment are due to failure of material below the bound layers of the pavement. One site visited as part of this study (Figure 4-3 and Figure 4-4) suggests that full reconstruction in some sections may be the only solution. Full reconstruction requires the replacement of all the bound layers and may extend into the foundation. It is likely that subbase defects, such as low CBRs, contamination, etc, mean that the subbase may need to be replaced.

Targeted treatment

It was noted during the site visits that some sections of pavement within a maintenance scheme were not treated, and this observation related to both single and dual carriageway schemes. It is assumed that these sections of the pavement were deemed to be defect free at the time of the design. Owing to budgetary constraints it may appear attractive to ‘sweat the asset’ or make best use of what already exists. However, there remains a real risk that owing to the age of the surfacing left in place, subsequent deterioration will lead to water infiltration and water retention that could cause damage to the lower layers. It is recommended that the age, type and typical service life of the surfacing should be considered, and if the material is within two or three years of its predicted service life it should be replaced.